SQ – Volume 1, Number 2 1997

Sandcarving Quarterly

Volume 1, Number 1 • 1996

Editor

April Sparr

Art Director

Adam Souders

Contributing Writers

Art Aguilar

Eric Jensen

Jim Jones

Billy Willis

Monica Willis

The Stage Carved Rose

A step by step guide to stage carving.

Steps To Success

Step by step instructions on the Patented InstaMask™ Process.

Tips and Secrets

Helpful hints and tips to help you be more productive.

Customer Spotlight

Visions makes their mark in the engraving industry.

Words to Live By

A Word from the Owner;

First of all, I want to thank all those customers, both great and small, for your continued patronage to our company. Rayzist® would not exist without each and everyone of you. Again, thank you.

I want to apologize for the lack of the personal touch, for which our company is known. You see, when we were small, we seemed to be able to take care of everything and help people in a more detailed manner. With our rapid growth, we seemed to have lost our personal touch. I have had customers invite me to weddings, stay in their homes when in their area, and spend quality time with them. It seems like those days have some how slipped away, and there is definitely something wrong with that. Again, I apologize if you have felt any of our growing pains. A change has been made and we are back to a small company attitude and are serving you in the best possible way. We are committed to each and everyone of you. Our products and services are, and will continue to be, superior to any other company in the world.

A few days ago, I had an experience with one of my customers that made me realize that we need to change from the top down. If I, being the leader, get upset with my customers, how are my customer service people doing? So changes have been made. Change is not always easy or welcomed, but it is necessary to better ourselves not only for our future, but also for yours.

Sometimes, it takes a good shot in the arm to wake you up. We have been serving our customers for over 12 years and I want to be doing this for 12 more. If we forget about whom we serve or forget to be thankful, we are missing the mark. Our goal is to please our clients, not just receive orders and ship them. The reason behind this newsletter is to bring people together and to help you do more with what you have, allowing you to be more profitable.

I hope this newsletter helps you. Feel free to call me with any suggestions or input concerning our newsletter.

Thank You,

Randy Willis

Owner

The Stage Carve Rose

Glass and crystal carving is among one of the most rewarding and satisfying art forms practiced today. The thousands who “ohh and ahh” over those delicately carved three dimensional pieces can only guess at the days or weeks required to produce each creation. Anyone who searched to uncover the secrets of glass carving discovered the consuming process of designing, tracing, hand cutting and carving. In 1983, Rayzist® Photomask introduced to the professional glass decorator a sandblast mask that vastly improved the existing hand and diecut stencils used for stage carving or dimensional glass carving. Rayzist® cut hours and days from glass decorators production schedules. Glass and crystal decorators quickly replaced the old hand cut techniques with Rayzist’s masking and found they were able to reproduce any black and white design or type into a work of art in a fraction of the time, effort and cost it took with hand cut stencils. But you don’t have to be a professional glass decorator to do stage carved pieces. All it takes is your creativity and the resources of Rayzist® Photomask to turn your artwork and glass piece into a masterpiece.

Glass and crystal carving is among one of the most rewarding and satisfying art forms practiced today. The thousands who “ohh and ahh” over those delicately carved three dimensional pieces can only guess at the days or weeks required to produce each creation. Anyone who searched to uncover the secrets of glass carving discovered the consuming process of designing, tracing, hand cutting and carving. In 1983, Rayzist® Photomask introduced to the professional glass decorator a sandblast mask that vastly improved the existing hand and diecut stencils used for stage carving or dimensional glass carving. Rayzist® cut hours and days from glass decorators production schedules. Glass and crystal decorators quickly replaced the old hand cut techniques with Rayzist’s masking and found they were able to reproduce any black and white design or type into a work of art in a fraction of the time, effort and cost it took with hand cut stencils. But you don’t have to be a professional glass decorator to do stage carved pieces. All it takes is your creativity and the resources of Rayzist® Photomask to turn your artwork and glass piece into a masterpiece.

Let’s take a look at how to stage carve any piece of glass with your design. The first thing that you will need is a pull chart of your design. This pull chart serves as your guide to successful stage carving. If you take a look at Diagram #1 you will notice that there are different numbers pointing to the many sections of the rose. These numbers tell you what to pull and when you need to pull them. Each pull also is a different depth of carving. If you don’t have a pull chart for your design, Rayzist® can supply you with one for about $35.00. We also carry a large variety of stage carvable stock designs that include the pull charts.

Let’s take a look at how to stage carve any piece of glass with your design. The first thing that you will need is a pull chart of your design. This pull chart serves as your guide to successful stage carving. If you take a look at Diagram #1 you will notice that there are different numbers pointing to the many sections of the rose. These numbers tell you what to pull and when you need to pull them. Each pull also is a different depth of carving. If you don’t have a pull chart for your design, Rayzist® can supply you with one for about $35.00. We also carry a large variety of stage carvable stock designs that include the pull charts.

The first step in this process is to prepare the glass piece for the carve. Take your glass piece and clean it with a glass cleaner, make sure to remove any dust or films that might be on the glass piece. This will allow for the glue on the stencil to adhere to your glass piece. Next, take your stencil and remove the cover sheet, exposing the glue. Center it on your glass, and burnish it. There are two types of burnishing tools: a metal ball burnisher and a plastic flat burnisher. For this piece we used both. First the metal one, to transfer all to masking and detail to your glass piece, then the plastic burnisher for a final sweep.

The first step in this process is to prepare the glass piece for the carve. Take your glass piece and clean it with a glass cleaner, make sure to remove any dust or films that might be on the glass piece. This will allow for the glue on the stencil to adhere to your glass piece. Next, take your stencil and remove the cover sheet, exposing the glue. Center it on your glass, and burnish it. There are two types of burnishing tools: a metal ball burnisher and a plastic flat burnisher. For this piece we used both. First the metal one, to transfer all to masking and detail to your glass piece, then the plastic burnisher for a final sweep.

After you have successfully transferred the stencil to your glass and removed the backing, place a few pieces of heavy duty duct tape over the open areas of your glass in order to prevent any over spray from the abrasive. Rub over the tape with your hand or a plastic burnisher to make sure that the tape is completely secure. If it is not secure there could be a possibility that some of the abrasive could get under the duct tape causing over spray.

After you have successfully transferred the stencil to your glass and removed the backing, place a few pieces of heavy duty duct tape over the open areas of your glass in order to prevent any over spray from the abrasive. Rub over the tape with your hand or a plastic burnisher to make sure that the tape is completely secure. If it is not secure there could be a possibility that some of the abrasive could get under the duct tape causing over spray.

Now you are ready to start your stage carve. For the best results, use a pressure blaster, which allows you to frost, carve, or cut as you require. If you are working with a pressure pot system, we recommend using about 25 to 30 lbs. of pressure. This will give you a nice, slow, cut and will allow you maximum control of carving. Looking at your masking, you should notice that parts of the design are open, while others are just outlines. The open areas are going to be your first and deepest carve. Before you start carving, look carefully at your pull chart (Diagram #1) if your are blasting the rose). You will notice that there are some areas that are shaded. These shaded areas indicate that you need to concentrate specifically in those areas. In these areas, you want to avoid any type of sharp or peaked cuts. To avoid this, blast in small circular motions. Try not to stay in one area too long, but rather move around nice and slow to ensure full and equal coverage.

Now you are ready to start your stage carve. For the best results, use a pressure blaster, which allows you to frost, carve, or cut as you require. If you are working with a pressure pot system, we recommend using about 25 to 30 lbs. of pressure. This will give you a nice, slow, cut and will allow you maximum control of carving. Looking at your masking, you should notice that parts of the design are open, while others are just outlines. The open areas are going to be your first and deepest carve. Before you start carving, look carefully at your pull chart (Diagram #1) if your are blasting the rose). You will notice that there are some areas that are shaded. These shaded areas indicate that you need to concentrate specifically in those areas. In these areas, you want to avoid any type of sharp or peaked cuts. To avoid this, blast in small circular motions. Try not to stay in one area too long, but rather move around nice and slow to ensure full and equal coverage.

After you have completed all of stage one, it is now time to move onto to the next stages of your blast. Refer to the pull chart, to see which pieces to pull first. Using an Xacto™ knife, peel off all of the masking that is labeled with a number 2. You will notice that some of the pulls in the number 2 areas are shaded. This tells you that you need to go deeper in those areas. Concentrate your nozzle in that area, moving in small circular motions, begin to carve out that part of the design. This will give you a three dimensional effect on the rose pedals. Before you start to do the leaves, take a look at the diagram. Notice how the nozzle is pointed and is cutting deeper at B. The carving is away from the end of the last blast. This will give you a layered effect. Do the same for 2a-2g. Remember not to allow much blasting over the area that you just carved, always cutting away in circular motions.

After you have completed all of stage one, it is now time to move onto to the next stages of your blast. Refer to the pull chart, to see which pieces to pull first. Using an Xacto™ knife, peel off all of the masking that is labeled with a number 2. You will notice that some of the pulls in the number 2 areas are shaded. This tells you that you need to go deeper in those areas. Concentrate your nozzle in that area, moving in small circular motions, begin to carve out that part of the design. This will give you a three dimensional effect on the rose pedals. Before you start to do the leaves, take a look at the diagram. Notice how the nozzle is pointed and is cutting deeper at B. The carving is away from the end of the last blast. This will give you a layered effect. Do the same for 2a-2g. Remember not to allow much blasting over the area that you just carved, always cutting away in circular motions.

Finish your piece by blasting the number 3 areas with a light frost. Remove your glass from the cabinet and check to see that you have completely blasted each area without leaving any areas unfinished. Strip away the tape and the masking, and rinse under warm water. Dry your glass piece with a soft cotton towel. Do not use paper towels, as they will scratch your glass or crystal piece. Take special care during clean up when working with lead crystal, due to the fact that it is much softer than glass and will scratch easier.

Rayzist® Photomask carries a wide variety of stock designs for stage carving, and if we don’t have the one you are looking for, our custom Art Department can help you to create what you want. We are dedicated to helping you with all of your sandblasting needs, whether it be engraving equipment or supplying mask, our main goal is to help you look good. When time, money, and quality counts the most, everything comes up roses when Rayzist® Photomask works for you.

Step to Success

Step 1: Artwork Development

Developing your own photomasks are not only easy, but very profitable. A quality photomask begins with quality artwork. Whether you create your artwork by hand, or design it in a computer, take time to double check these two items: Is the artwork clean? (No halftone or gray areas – just black and white) and will my film tool work? You may use a kodalith film positive or our special U.V. vellum.

Developing your own photomasks are not only easy, but very profitable. A quality photomask begins with quality artwork. Whether you create your artwork by hand, or design it in a computer, take time to double check these two items: Is the artwork clean? (No halftone or gray areas – just black and white) and will my film tool work? You may use a kodalith film positive or our special U.V. vellum.

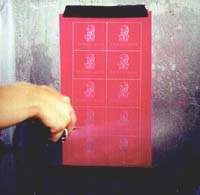

Step 2: Exposing InstaMask™

Once your artwork is on a vellum or film positive, the design can be trans-ferred to InstaMask™ Paper Back or InstaMask™ Clear photo resist. Simply contact the ink side of the vellum or film with the InstaMask™ material and expose it with your U.V. exposure unit for the designated time.

Once your artwork is on a vellum or film positive, the design can be trans-ferred to InstaMask™ Paper Back or InstaMask™ Clear photo resist. Simply contact the ink side of the vellum or film with the InstaMask™ material and expose it with your U.V. exposure unit for the designated time.

Step 3: Processing

More commonly known as washing out, this process will “develop” the image you just exposed. You can do this by either using our hand held spray assembly or one of Rayzist’s automatic spin processors. The spin processors use pressurized water to wash out the InstaMask™, taking about 1.5 minutes per cycle. Washing out with the hand sprayer will take 1.5-2 minutes, using warm water, keeping a distance of 4″-6″.

More commonly known as washing out, this process will “develop” the image you just exposed. You can do this by either using our hand held spray assembly or one of Rayzist’s automatic spin processors. The spin processors use pressurized water to wash out the InstaMask™, taking about 1.5 minutes per cycle. Washing out with the hand sprayer will take 1.5-2 minutes, using warm water, keeping a distance of 4″-6″.

Step 4: Drying Process

After processing the InstaMask™ photo resist, you must allow it to dry. This cures the material and makes it ready for sandblasting. In a hurry? Use one of our dryers to do several sheets at a time. Otherwise, having blotted the excess water from the sheet, we recommend air drying the InstaMask™ in a dry room for about 1 hour. If time is short and you do not have a Rayzist® dryer, microwave your sheet on low power for 10 minutes. This will evaporate the moisture from the InstaMask™ material. Air drying will give you the best result.

After processing the InstaMask™ photo resist, you must allow it to dry. This cures the material and makes it ready for sandblasting. In a hurry? Use one of our dryers to do several sheets at a time. Otherwise, having blotted the excess water from the sheet, we recommend air drying the InstaMask™ in a dry room for about 1 hour. If time is short and you do not have a Rayzist® dryer, microwave your sheet on low power for 10 minutes. This will evaporate the moisture from the InstaMask™ material. Air drying will give you the best result.

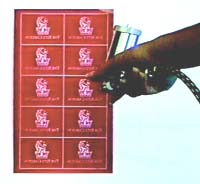

Step 5: Adhesive Application

When the sheet of InstaMask™ is dry, the adhesive can be applied. This may be accomplished by one of two simple methods. Method 1: Use our RZ-2 water based adhesive with our easy to use InstaMask™ sprayer to spray a light coat directly on to the stencil. Method 2: Apply the adhesive onto the item that the stencil is going on. Use either a foam brush or fine bristle paint brush to apply a very light even coverage of adhesive. Which ever method is chosen, allow the glue to set 2-3 minutes before blasting.

When the sheet of InstaMask™ is dry, the adhesive can be applied. This may be accomplished by one of two simple methods. Method 1: Use our RZ-2 water based adhesive with our easy to use InstaMask™ sprayer to spray a light coat directly on to the stencil. Method 2: Apply the adhesive onto the item that the stencil is going on. Use either a foam brush or fine bristle paint brush to apply a very light even coverage of adhesive. Which ever method is chosen, allow the glue to set 2-3 minutes before blasting.

Step 6: Transferring the Stencil

When using Rayzist’s Paper back material, just position the stencil on the item and then burnish it down with a Rayzist® metal burnisher. When using our Clear back material, simply rub down the stencil with a plastic burnisher and then peel off the clear backing sheet. By flicking a corner of the mask, the carrier is loosened, making removal easy.

When using Rayzist’s Paper back material, just position the stencil on the item and then burnish it down with a Rayzist® metal burnisher. When using our Clear back material, simply rub down the stencil with a plastic burnisher and then peel off the clear backing sheet. By flicking a corner of the mask, the carrier is loosened, making removal easy.

Step 7: Blasting

We recommend 20-30 psi blasting pressure for most items, holding your nozzle about 4-6 inches away. Blast until you have a nice, even depth across the design areas of the stencil. You can achieve 1/8″ to 3/32″ depth using our 5 mil material. 180 grit aluminum oxide works best for sandblasting a wide variety of materials. A pressure pot system gives you superior control and the best results. Good size sandblast nozzles are 1/16″-1/8″ maximum.

We recommend 20-30 psi blasting pressure for most items, holding your nozzle about 4-6 inches away. Blast until you have a nice, even depth across the design areas of the stencil. You can achieve 1/8″ to 3/32″ depth using our 5 mil material. 180 grit aluminum oxide works best for sandblasting a wide variety of materials. A pressure pot system gives you superior control and the best results. Good size sandblast nozzles are 1/16″-1/8″ maximum.

Step 8: Clean Up

After you finish sandblasting, you’re ready to clean up the blasted item. You will get the best results if you put the blasted items in a sink of warm water and let them soak for several minutes. The stencil will remove easily after soaking. You can also just peel the stencil away from the item by gently rubbing your fingers over the mask. Be careful not to scratch your piece when handling it. Dry abrasive residue can cause small scratches in the surface of the blasted item.

After you finish sandblasting, you’re ready to clean up the blasted item. You will get the best results if you put the blasted items in a sink of warm water and let them soak for several minutes. The stencil will remove easily after soaking. You can also just peel the stencil away from the item by gently rubbing your fingers over the mask. Be careful not to scratch your piece when handling it. Dry abrasive residue can cause small scratches in the surface of the blasted item.

Tips and Secrets

• InstaMask™ not washing out properly

Make sure your laser printer or copy machine is printing opaque enough onto your vellum. It must be dark enough to properly shield the light when exposing. Transparency film does not give good results when used as a film tool unless the detail (as in text) is extremely thin.

Make sure your laser printer or copy machine is printing opaque enough onto your vellum. It must be dark enough to properly shield the light when exposing. Transparency film does not give good results when used as a film tool unless the detail (as in text) is extremely thin.- Do not process the InstaMask™ under direct or indirect sunlight. This will rapidly expose the material due to the high U.V. content of sunlight. (No special darkroom or yellow lighting are needed).

- Be sure and use the proper spray assembly. Low water pressure will give poor results for processing InstaMask™.

• Stencil coming off of the item while blasting –

- Be sure to use the proper burnishing tool to transfer the stencil to the item. A hard metal burnisher gives the best results.

- Coat a thin layer of adhesive onto the mask.

- Apply adhesive with the InstaMask™ spray assembly.

• Problems blasting the adhesive out of the open areas –

-

If your adhesive gets too thick it may begin to act as a resist in the open areas.

- Siphon system and pen size blasting users often experience more difficulty when blasting the adhesive out of the open areas. Increasing the blasting pressure will help to remove any adhesive that seems “stubborn.”

- Remove excess glue by using a cotton swab and some alcohol or thinner to target problem areas.

• Blasting on tight curves –

When having to blast on items with severe curves, try using Instamask™ Clear. By separating the clear backing from the masking, the stencil will be easier to apply. A thin, clear layer of material ensures that all of your detail stays in position while you place the mask on the curved surface.

• Vellum vs Film Transparency –

Your film tool is key to the mask making process. It is absolutely critical that you have opaque enough black areas in your design. Holding the vellum up to a light source, on to a light table to see the amount of light passing through the black areas. If too much light penetrates the black areas you will be unable to produce a good mask. We recommend that you do not use a transparency film for your film tool because the toner from copiers or printers do not always transfer to the transparencys well enough. When exposing with the transperency, the ink tends to flake off. We recommend that you use our special U.V. vellum paper or a kodalith film positive. Both of these products will give you optimum results.

Customer Spotlight: Visions of Success

Visions of Success…

Visions of Success…

That is what Tom Meyer had when he started his company 6 years ago using just half his garage (his wife, Dana, reluctant to forfeit her car space). Since then, Visions has grown to 50 employees, more than making their mark in the corporate gift world. Meyer’s distinct use of marble slate, fossil stone, glass, and crystal has been transformed into a full line of corporate awards, plaques, and eye catching gifts. From exotic book ends, marble cased clocks, to metal masterpieces, Visions offers a full in house production of customized gifts, as well as engravable blanks for anyone to purchase and engrave on their own.

The Rayzist® Result:

The Rayzist® Result:

Having experimented with other masks on the market, Tom says, “Rayzist® has always given me great service and a good product. Their mask is the best because application is easy. It holds up to sandblasting better and cleans up faster. If you’re doing any kind of production work at all, you’re missing it by not using Rayzist®.” Visions uses Rayzist’s InstaMask™ Clear as well as our sandblasting cabinets, wash-out units, exposure units, and spray glue assembly.

For more information on Visions and all their products, contact them at (419) 586-6433.