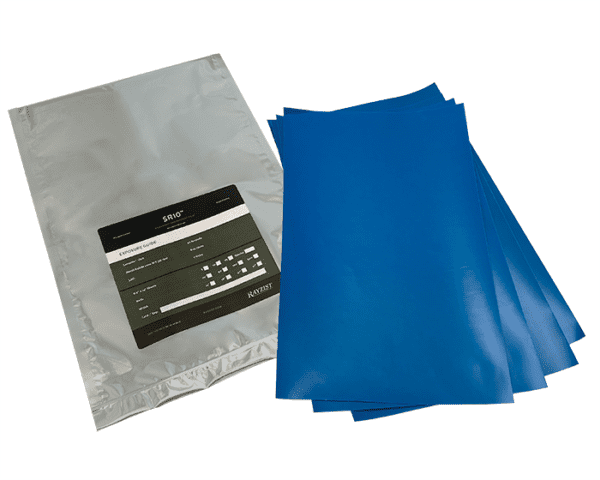

SR3000™ Photo Resist Film

Starting at: $53.55

SR3000™ Overview

We call it Self-Stick film, but you might call it amazing. SR3000 is a repositionable, self-stick film that does not carry or require a stubborn, messy adhesive—that means no residue clean-up, no complicated handling issues, and no adhesive to apply or over-wash. There’s simply nothing else like it in the marketplace today. The film develops a slight tack after wash-out, but will never feel gummy or sticky.

SR3000 has industry-leading durability and resolution capabilities—you can trust it with half-tone images or ultra high resolution images, for deep etches or fine details, and on flat or curved surfaces. The 3 mil thickness is designed to push the envelope in high resolution designs; you can blast finely detailed images without the worry of pinhole blast-through. Use the 5 mil to achieve a deeper etch or multi-stage carving. You will be thrilled with the results.

Processed SR3000 clings steadfastly to any polished surface, providing an ideal system for creating fine quality engravings on glass, wood, stone, ceramic, granite, marble and soft metals.

The efficiency advantage

From exposing to blasting, SR3000 helps you get it done faster, more efficiently than ever before. It saves you money because it saves you time.

- Manufacture direct film support

- Easy application/User friendly

- No special lighting neccessary

- Versatile

- Repositionable

- Durable

- Flexible for curved surface

- Fast exposure

- Quick washout

- Excellent detail

- Multistage carving

- Cost effective

Additional information

FAQs

Can I use my current exposure system in place of the Letralite Unit to process the photoresist film?

Other exposure systems can work for this process. The exposure system must have a vacuum or compression feature and an opaque mat/pad.

Do I need to use a dark room to handle the photoresist film?

A dark room is not needed for this process; photoresist film is white light tolerant. The photoresist film can be exposed to fluorescent or LED lighting for a limited time. Do not expose photoresist film to direct or indirect sunlight.

Can I washout the photoresist film outside?

Photoresist film will cure when exposed to UV light, even under overcast weather. Develop the photoresist film indoors protected from a window or skylights.

What type of printer do I need to print my artwork?

An opaque print is key to producing a photomask. We recommend inkjet printers since you can adjust the print settings to print an opaque print.

Do I need a special paper to print my artwork?

A UV approved clear film such as Inkjet film for inkjet printers must use for this process. For laser printers used Laser Film or UV Vellum. Do not use paper to print artwork. Note: Color laser printers and Brother brand tend to not work for this process. If you use a laser printer, the print must be opaque.

Do I have to use the Rayzist Hand Sprayer to washout the exposed film?

It is recommended to use the Rayzist Hand Sprayer for this process. The Rayzist Hand Sprayer provides a pressurized fan spray that is required to properly washout the photoresist film. Most standard sprayers such as a kitchen sprayer will not provide enough

pressure to washout the film.

Can this film be used for chemical or acid etching?

Photoresist films are designed exclusively for sandblasting applications and cannot be used for chemical or acid etching. There is a thin membrane that holds the design together until sandcarved. The membrane acts as a barrier for acid or chemical etching.

Features

Manufacturer Direct Film Support

Rayzist produces all photoresist films in USA since 1983.

Light Safe Tolerant

No darkroom needed.

Versatile

Use SR3000™ Photoresist Film on multiple materials. Achieve light frosting to deep etching on crystal, glass, natural stone and wood. SR3000™ Self-Stick film provides optional Color Fill application.

Excellent detail

Maintains the quality of original halftone or vector images.

Rapid Exposure

Exposure times are quick, 20 seconds exposure on a Letralite Unit™.

Quick Washout

The washout process is streamlined for maximum efficiency. Provide a ready to use photomask fast.

Flexible Curved Surfaces

SR3000™ Photoresist Film is the most flexible sandcarving film available. Use it on flat or curved or tapered surfaces.

Repositionable

SR3000™ Photoresist Film is a repositionable sandcarving film. Apply SR3000™ photomask to the surface and realign multiple times if needed. Squeegee photomask once in place. Sandcarving is quick since there no layer of adhesive. Peel photomask stencil easy with no residue.

Durable

SR3000™ Photoresist Film is designed to be strong and long lasting. Depending on the Mil thickness, SR3000™ can endure Aluminum oxide or Silicon carbide 220, 180, 150 & 120 grit abrasive.

Multiple Thicknesses

SR3000™ Photoresist Film is available in 3Mil, 4Mil & 5Mil.

3Mil is ideal for fine detail and half-tone images.

4Mil is perfect for moderately detailed artwork that requires a moderate depth etch.

5Mil is appropriate for artwork requiring a deep etch.

Multi-Stage Carving

SR3000™ Photoresist Film is perfect to achieve a Multi-Stage carve due to the easy peel or removal of the Self-Stick film.

Technical Details

Directions

Expose SR3000™ Photoresist Film to printed artwork with Letralite Unit, washout exposed photoresist and dry. Once the film is dry apply to substrate and sandcarve.

Abrasive

Aluminum Oxide or Silicon Carbide is the preferred abrasive to use with SR3000™ Self-Stick photoresist film. The recommended grit size is 120grit to 220grit.

Color Fill Application

SR3000™ Photoresist Film allows a color fill application after sandcarving. Just leave the photomask on the substrate after the surface is etched and add a spray or hand paint application. Remove the photomask after the paint has dried.

Handling

SR3000™ is a UV light sensitive photoresist film. Sunlight will overexpose the SR3000™ film. SR3000™ can be handled under fluorescent lighting for a limited time or under yellow lighting with no limitations. SR3000™ is a water-soluble film.

Support

Why am I experiencing long washouts with SR3000™ Photoresist Film?

A – The SR3000™ is a light sensitive film. Do not wash film outside, indirect or direct UV light will expose film at a fast rate.

B -Wash film with Rayzist hand sprayer which produces a pressurized fan spray. Pressure is important for developing film. Rayzist hand sprayer recommended distance is 1 – 2” from exposed film.

C – Confirm you have a dark opaque print.

D – Exposure time on a Letralite™ unit is 20 seconds and Luminex 1422 exposure unit is 6 seconds.

How can I tell if my print is dark enough for the process?

A – Hold your print up to light and confirm no light is passing through. If light is passing through double check your print settings to ensure you have the darkest print setting possible.

B – Color laser printers are not recommended as they often do not print a true black.

Why does the SR3000™ stencil/mask feel dry?

A – If the SR3000™ stencil/mask feels dry, reactivate the adhesive by applying the mask to a damp lint free cloth.

B – Apply Cover Paper (backing paper) SR3000™ photoresist stencil/mask once the sheet is dry. This will preserve the self-stick properties.

Antonio Luna –

This product is the best, I used all the time to etch wine bottles, never had have any problem.

Creative Indulgence –

Fantastic product, easy to work with. Makes all our sandblasting projects much easier to blast. We have used 3 mil, 4 mil and 5 mil, when you have such a great product it makes our work effortless.

The customer service is amazing too. Thanks Rayzist !!! So happy to have found you for our 2034VXA SAND CARVING SYSTEM and sand carving products.

PS Liz 10 stars… !!

Mike –

Great product, easy to use.

KeiShei –

I am new to sandblasting and ordered this as my first venture. I was told it is the best material. I currently do laser engraving and am trying this on it.

Hammond Glass Engraving –

Great product–easy to us. Our shop uses the 4 mil and heavier weights as well for deeper etchings. We appreciate the knowledgeable and helpful staff.

James Goodman –

Tried other resists but keep coming back to SR-3000.

Lewis Nash –

Great product. Easy to use. I don’t waste time smearing glue on the bottle hoping I covered all the area covered by the stencil. After blasting, I soak the bottle in water . The stencil usually peals right off. Any left-over adhesive comes off with Charlie’s Soap. The blasted lines are crisp and the detail is sharp. GREAT PRODUCT!!!! GREAT COMPANY!!!

William Prues –

Material was excellent and thanks for getting it out quickly.

Mark Riley / Blast Wares –

The SR3000 film is an amazing product! I’ve used other films but not been able to hold detail like I can with this product!

Carol McCracken –

This is the greatest resist. So easy to use from exposing to very easy removal. Never have any waste and that’s important.

Scott D. –

great product. It works just like it should.

Peter Kurzhal / Accent Awards –

I have used other Masks but now only the SR3000. It is so rare that I experience blow-off with fine detail while using this product whereas other masks were a big problem. Over the years I have experimented again with others when they offered free trial product samples with the thought that I have more experience now and perhaps I was doing something wrong in the past. Well, 25 years in the business has taught me to stay with products that are consistently good and for the past 7 years it has been SR3000 exclusively.

Ryan Hoffman –

Thank you for producing a fantastic and reliable product. We use the sr3000 rapid mask weekly and it’s great.

Deano / Etchings by Deano –

I have tried competitors product and it does not compare with the sr3000 in any way. Easy to work with and provides a superior etch with no specs every time.

Antonio –

I use SR-3000 all the time, ease to work with, very good product! Easy to remove, I really love it.

Jim Adlhoch –

Their photo resist film is top notch. A competitor sent me film that was supposed to be superior to the SR3000 film from Rayzist. The only thing it had in common is that it came in a light proof bag – there was no comparison. Rayzist SR3000 film is consistent, easier to work with, and though adheres well, comes off easily post-blasting without having to soak the piece in warm water to get the mask off, as has to be done with the competing product.

Peter C. –

SR3000 Rocks! Washes out great and works great.

Ken W –

The SR 3000 mask material is great to work with. We use nothing else.

Beth-Arne Lundgren / BAL Studio Glassliperia –

Excellent product and easy to work with. Perfect for me when I sand blasters photo images, and more detailed images.

Jerry L. Gray –

Razist SR3000 great product. I have been using the sr3000 photomask for a while now, I think this is a great product, the repositioning factor of the self adhesive saves a lot of stencils. Great product!

Patrick –

Very good product. It was able to with stand up to 30 psi in sand blaster and still held a sharp image on glass for pate de verre artwork or relief sculpture on glass.

Jim A. –

SR-3000 pulls off the work very easily with minimal weeding. Most weeding with SR-3000 can be with a piece of blasting tape or blade. If you have a long strip of film on the object, it generally comes off in one long piece of masking material. The Ikonics mask is rather difficult to remove. It doesn’t come off easily, breaks/tears apart when pulled, and I ended up having to wash it all off — a real mess. I did try rubbing it off with my fingers and it just forced mask into the design. The same thing happened when I ran the piece under hot water to get the Ikonics mask off — I spent time cleaning mask out of the design there, too.

I did identical blasting pieces, one with SR-3000 and another with Ikonics — no comparison — Rayzist has the better product.

Jim A. –

SR-3000 pulls off the work very easily with minimal weeding. Most weeding with SR-3000 can be with a piece of blasting tape or blade. If you have a long strip of film on the object, it generally comes off in one long piece of masking material. The Ikonics mask is rather difficult to remove. It doesn’t come off easily, breaks/tears apart when pulled, and I ended up having to wash it all off — a real mess. I did try rubbing it off with my fingers and it just forced mask into the design. The same thing happened when I ran the piece under hot water to get the Ikonics mask off — I spent time cleaning mask out of the design there, too.

I did identical blasting pieces, one with SR-3000 and another with Ikonics — no comparison — Rayzist has the better product.