CARVE YOUR STORY!

Rayzist Photomask has been building relationships and Sandcarving businesses since 1983. Starting a Sandcarving business is a low investment with an easy learning curve. Our experienced and knowledgeable team is ready to help get you started.

Support

- Training videos on our YouTube.com/Sandcarving channel

- Hands-on workshops at Rayzist Photomask

- How to articles

- Technical support

The Many Surfaces of Sandcarving

The Sandcarving engraving method offers a wide range of products and industries. Whether you are creative or not so creative Sandcarving with photoresist film allows you to create beautiful, simple, or detailed imagery in various materials. Personalize spirit, wine and champagne bottles with a simple Happy Birthday, Congratulations or Happy Anniversary.

Barware is another ideal product to Sandcarve. Glasses, wine glasses, decanters, whiskey glasses, ceramics mugs and more.

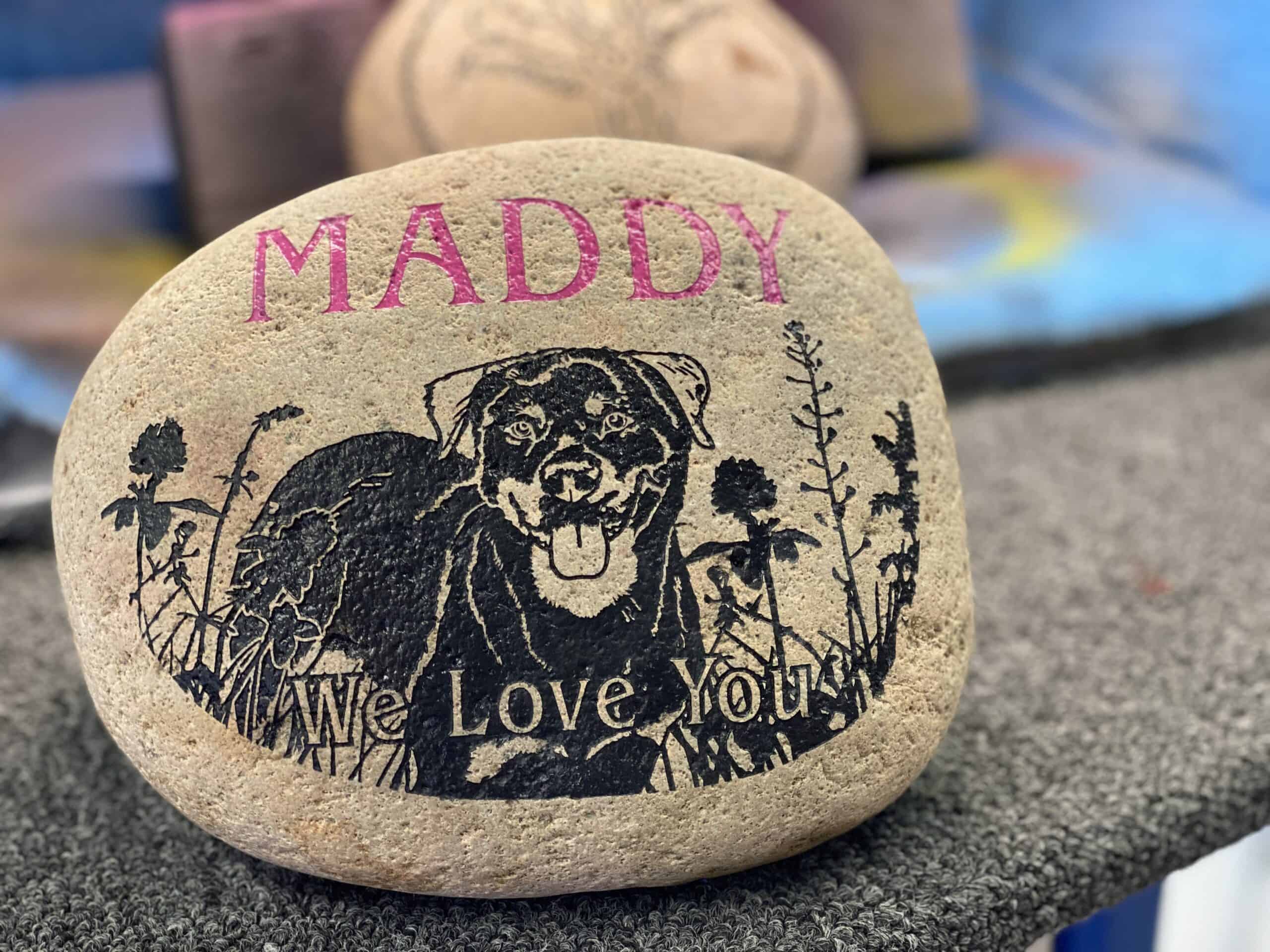

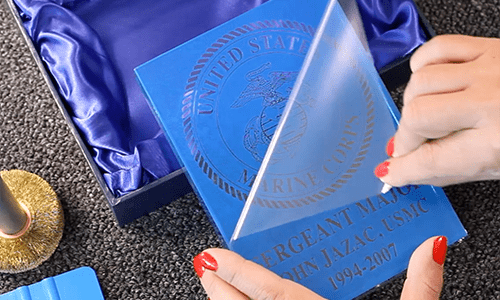

Sandcarving creates depth in glass, crystal, stone and wood. The depth is the wow factor in the etched product. Add a Color Fill to create a contrast on darker materials such as stone, wood or wine bottles.

Natural Stone such as granite, tile, river rock, brick look great Sandcarved. Donor recognition, signage, pet memorials or garden rocks are ideal products to Sandcarve. Sandcarving allows depth in natural stone with an optional Color Fill. Photoresist film or LazerMask is also flexible and can be applied to a curved shape.

Preparation in 3 Easy Steps

Apply Mask

Squeegee Mask to Substrate

Remove Protective Liner

Frequently Asked Questions

Getting Started

Masking Kits

Graphic Programs

Sandcarving System

Printers

Lazer

Getting Started

What do I need to get started?

Rayzist makes starting a Sandcarving business easy with our multiple equipment packages. You only need a few items: a sandcarving system, mask making kit, air compressor, printer and graphic program.

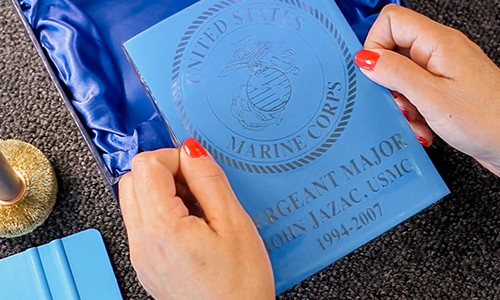

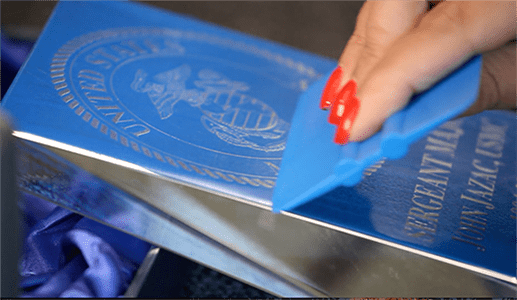

Starting a Sandcarving business requires limited investment, it’s low maintenance, and relatively straightforward. A Sandcarving system combined with our photoresist film will allow you to achieve an engraved depth on virtually any surface such as crystal, glass, natural stone, wood, fused glass, blown glass, stained glass, and much more. All metal surfaces can be sandcarved, but you will not achieve depth, you will only etch away the top surface/coating/plating and leave behind a satin like finish, the same would be true on plastics.

Where do I get Sandblasting stencils (Sandcarving masks)?

- Produce your own photoresist stencil.

Our mask making kits include everything you need to start creating your own photoresist stencils (other than a graphic program and printer). Print a black and white (black = blast) vector image on our print film, expose the print film to the photoresist film, and develop by washing out the image. Once the photoresist is dry, apply it to your substrate and sandcarve.

- Use our Custom Mask Service

Our Custom Mask service is convenient and easy to use. Just email your artwork to us and we will send you finished stencils, ready to sandcarve. We can produce any size up to 40”x50” in small or large quantities. When “time in money,” this service will easily pay for itself.

- Use LazerMask with your Co2 Laser Engraver

LazerMask is our sandblasting film made specifically for laser engravers. There is no photo process development: apply LazerMask to the substrate, laser (Vector or Raster) the design and sandcarve. The LazerMask is easy to apply and remove, plus it gives you the option to paint fill the etched area. Co2 and Fiber lasers can be used and in combination to mark metal surfaces and add an industrial coating like enameled paint fills.

Note: Vector images will require weeding and a Raster image requires weeding of the design. Raster images are used in most cases.

Graphics

What type of graphic program do I need?

A printer is required to print artwork for the mask making process. It is important to have a very dark print from your printer for this process.

Mask Making

What is a Mask Making Kit?

The Mask Making Kit is equipped with the proper tools to produce your own Photoresist stencils / masks. The Mask Making Kit includes a Letralite Unit, Hand Sprayer and Washout Board which are proven tools to create consistent Photoresist stencils successfully.

In addition to the Mask Making Kit, you will need a graphic program such as Adobe Illustrator, CorelDraw or Affinity Designer to produce black and white vector images. You will also need an Inkjet printer.

Can I use any exposure system in place of a Letralite Unit?

The Letralite Unit is the most common exposure unit to produce Photoresist stencils. However, there are several various types of exposure systems available, some will work for this process and others will not work. Letralite units provides even tension for the photoresist and print around the cylindrical shape of the exposure frame.

View the Luminex 1422 exposure system for more accurate vacuum compression. Vacuum compression allows for more accurate contact and yield better image resolution of the Photoresist stencil.

With other exposure systems the exposure time is unknown, tests will need to be performed on proper exposure times.

Are they any limitations to using a Letralite Unit?

The Letralite Unit has a max exposure area of 10” x 14”. Use the Custom Mask Service at Rayzist for larger images.

How skilled do I need to be with a graphic program?

To have a successfully photoresist stencil it begins with the artwork. You should have basic skills of your graphic program. If you have no skill of a graphic program, then search the internet for training videos and practice. There are subscription-based training videos available that will help you use your graphic program successfully.

Do I have to create my own artwork?

You can purchase artwork or create your own. There are many sources for vector artwork available. Websites such as Vectorstock.com and Shutterstock.com and many others have several vector images to choose from. Most of these sites offer royalty-free images and commercial licensing for a fee.

If you lack skill in a graphic program, then select images that are in black and white with no gradient or color. The black and white images will be easier to set up in your graphic program

Printers

What type of printer do I need?

We recommend inkjet printers for this process. Inkjet printers allow you to change the print settings, giving you more options for an opaque print. Inkjet print film is also clear, giving you the best detail possible in photoresist film. When choosing an inkjet printer, make sure it will print on transparencies this feature will ensure the printer will print on the clear inkjet film. Some consumer-based Inkjet printers have print sensors, which prohibit the use of clear printing film.

Note: We do not recommend laser printers due the printing of light prints. Light prints will not produce a quality photoresist mask.

Sandcarving Systems

What type of Sandcarving system is right for me?

First, how much Sandcarving do you see yourself doing? If you plan on having a business of offering etched product and blasting for 2+ hours per day than you need to look at systems with premium dust filtration such as the 2034VXA for best results. Second, what size items do you see yourself sandblasting? If you plan on sandblasting large items, then this will determine what size blasting cabinet will meet your needs. Our 1924 Sandcarving system is equipped with a 24”W x 24”H x 19”D blasting area, compared to the 2034VXA has a large cabinet measuring 34”W x24”H x 22”D. The size of the cabinet limits what size items you can blast. Remember you can blast small items in a large cabinet, but you cannot blast large items in a small cabinet.

Rayzist manufactures the cleanest and highest quality systems available today. Every system is self-contained, recycles abrasive and includes a dust filtration system. We offer three sizes, each one with your specific needs in mind. They are available in 110volt and 220volt (for international destinations). All of our Sandcarving machines are pressure pot systems. The Sandcarving system removes the surface of the substrate creating depth etching the surface.

What size air compressor do I need?

What maintenance is required on Rayzist Sandcarving system?

Can I use any sandblast system?

There are several sandblast systems available and with a wide price range. Typically, a search for sandblast systems will result in Siphon systems which are industrial type equipment designed to remove paint, rust or resurface. In many cases these systems leave you with finding a dust filtration and no technical support. Industrial sandblast systems are equipped with large nozzles (often ceramic), large blast hoses and consume 3x more air which makes it difficult to sandcarve detailed images.

We recommend and use direct pressure Pressure Pot systems with a 3/32 nozzle and a pressure regulator which controls your blasting pressure. Rayzist Sandcarving Systems are designed for the decorative/personalization markets, etching glass, crystal, stone, wood, metal, and other fine products. The premium lighting, media separation, and dust filtration allows you to view the etching inside the cabinet and have a clean working environment.

What is the difference between a Pressure Pot system and Siphon system?

Siphon Blaster

Siphon blast systems operate with the principle of low surface impact different than a direct pressure blast pot. A Siphon blast pot using a handgun with larger nozzles it also draws material via suction into the stream of air instead of the blast media being pressurized via direct pressure. Siphon blasting are most effective for cleaning application and not designed to etch depth into glass or stone due to the low impact effect.

Pressure Blast Pots

Pressure Pots are sealed pressure vessels and build pressure that is provided by a compressor. The pressurized air is pushed out of the blast hose where media is mixed with the air. Pressure blasting has a variety of benefits over a Siphon sandblast pot. Pressure blast pots are faster than Siphon blasters because they cause blast media to impact the surface of a product with a lot more force. The increased force that media will impact the surface allows you to sandcarve faster from a surface etch to deep etch. Some would think direct pressure would use more compressed air, but it uses about half the volume of airflow required to operate verses a Siphon system. Rayzist Sandcarving Systems use only pressure pots that are ASME rated (American Society of Mechanical Engineers). ASME rating ensures that your sandblast pressure pot will safely tolerate high pressure. Pressure pot systems are priced higher in cost in comparisons to a Siphon blast pot. The higher cost is a result of a welded and ASME certified pressure vessel.

Can I use the Rayzist 100lb Portable Pressure Pot with my existing blast cabinet?

Note: Use proper protection (face mask, gloves and breathing helmet) when operting a portable pressure pot outside of a blasting cabinet.