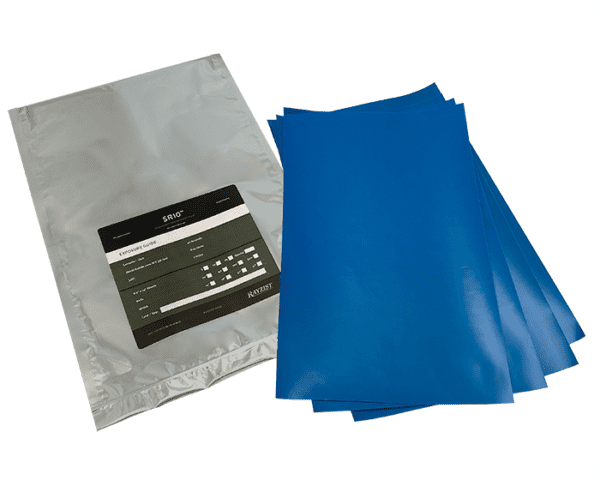

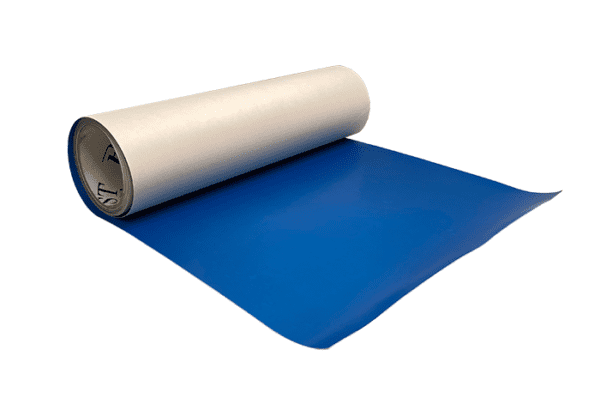

SR2000™ Photo Resist Film

Starting at: $52.60

SR2000™ is simply the industry’s sturdiest sandcarving film. It is user-friendly; non-stick formulation that you can trust to withstand the demands of your deepest etches and hardest surfaces. Known as “Original Blue,” SR2000 is a legacy product that has earned a loyal fan base among Rayzist customers. Use it for glass, wood, stone, ceramic, granite, marble, soft metals, and curved or flat surfaces. SR2000™ patented non-stick surface streamlines processing, without limiting your ability to carve fine details and compelling etches on a variety of materials. SR2000™ is the preferred photoresist film when a high tack bond is required to secure the photomask to substrate. This high tack bond is ideal for unpolished, porous, uneven natural stone surfaces.

SR2000™ patented non-stick surface streamlines processing, without limiting your ability to carve fine details and compelling etches on a variety of materials. SR2000™ is the preferred photoresist film when a high tack bond is required to secure the photomask to substrate. This high tack bond is ideal for unpolished, porous, uneven natural stone surfaces.

Additional information

| Weight | N/A |

|---|---|

| Dimensions | 1 × 1 × 1 in |

| Style | |

| Thickness | |

| Dimension | 14 in x 8 ½ in (5 Sheets), 14 in x 8 ½ in (10 Sheets), 14 in x 8 ½ in (25 Sheets), 14 in x 25 ft (1 Roll), 14 in x 50 ft (1 Roll), 14 in x 100 ft (1 Roll) |

FAQs

What is the difference between SR2000™ and SR3000™ Photoresist Film?

SR2000™ has no adhesive in the film and RZ2 adhesive must be applied by brush. SR3000™ is a Self-Stick film that is pressure sensitive.

Why use SR2000™ Photoresist Film over SR3000™ Self-Stick film?

SR2000™ is often used for aggressive blasting and unpolished surfaces. SR2000™ is available in thicker material for deep sandcarving. SR3000™ commonly

used for glass, crystal, metal or polished surfaces.

Is adhesive required with SR2000™ Photoresist Film?

A – SR2000™ Photoresist film requires an application of RZ2 brush-on adhesive or RZ3 spray-on adhesive.

B – RZ3 adhesive is used in an Automotive or a Touch Up Spray Gun sprayer. A spray booth with filtration system is recommended with RZ3 adhesive.

How much adhesive is required to use with SR2000™ Photoresist Film?

Generally a light layer of RZ2 adhesive is sufficient for sandcarving. For unpolished and porous surfaces, apply an extra layer or more of adhesive as needed for the project.

What is the best method for applying RZ2 brush-on adhesive?

Use a paint brush not a foam brush to apply a light coat of adhesive to photomask. Apply an even coat of adhesive and let dry. Adhesive will appear white and turn clear when dry. Clean brush after use of adhesive.

How do you determine what mil thickness to use of SR2000™ Photoresist Film?

The recommended Mil thickness of photoresist film depends on the detail of the artwork and the required blasting depth for the project.

5Mil – is for bolder artwork and lettering. Moderate to deep stage carving is recommended when using 5Mil photoresist film; works best with wine bottles, ceramic, multi-stage carving, stone, tile, and granite surfaces.

6Mil – is designed for bold artwork and lettering. The 6Mil is perfect for deep carving on stone, tile, granite and natural stone. The 6Mil is the preferred thickness for carving pet memorials and donor recognition projects.

9Mil – is designed for bold artwork and lettering. It is durable to handle a high pressure sandcarve for a deep carve with a coarse grit. The 9Mil is often used by monument sandblasters.

Features

Manufacturer Direct Film Support

Rayzist produces all photoresist films in USA since 1983.

Industry-Leading Durability

SR2000™ Photo Resist film is durable and will endure high pressure blasting with a coarse abrasive.

Light Safe Tolerant

No darkroom needed.

Versatility

SR2000™ Photo Resist can be used on many surface types.

Excellent Detail

One to one image transfer.

Rapid Exposure

Exposure times are low for SR2000™ Photo Resist Film.

Quick Washout

The washout process is streamlined for maximum efficiency. Provide a ready to use mask quickly.

Easy Application

No need to struggle with carrier release.

Adhesive Strength

Determine the bond strength for the project. Apply RZ2 brush-on adhesive to photomask stencil. RZ2 adhesive provides a strong tack for the photo resist stencil to adhere to unpolished surfaces or an aggressive sandblast. RZ3 spray on adhesive is also available.

Recommended Materials

SR2000™ Photo Resist film in 5 Mil & 6Mil is ideal for metal, powder coated metal, acrylic, glass and wood materials.

Stone Surfaces

SR2000™ Photo Resist film in 6Mil & 9Mil is ideal for natural stone and uneven surfaces. Sandblast depth into granite, brick, pavers, tile and all stone materials.

Monument Standard Depth

Use SR2000™ 9Mil Photo Resist Film to sandblast depth on memorial stones.

Fast Clean Up

No solvents needed.

Technical Details

Directions

Expose SR2000™ to printed artwork with Letralite Unit, washout exposed photoresist and apply adhesive once dry. Apply RZ2 brush-on or RZ3 spray-on adhesive to the dry surface. Add a light to heavy layer of adhesive depending on the desired bond strength needed for substrate. Apply photomask to substrate and sandcarve.

Abrasive

Aluminum Oxide or Silicon Carbide is the preferred abrasive to use with SR2000™ photoresist film. The recommended grit size 120grit to 220grit.

Color Fill Application

SR2000™ Photoresist Film allows a color fill application after sandcarving. Just leave the photomask on the substrate after the surface is etched and add a spray or hand paint application. Remove the photomask after the paint has dried.

Handling

SR2000™ is a UV light sensitive photoresist film. Sunlight will expose the SR2000™ film. SR2000™ can be handled under fluorescent lighting for a limited time or under yellow lighting with no limitations. SR2000™ is a water-soluble film. SR2000™ has a one year expiration date from the time of purchase.

Support

Why am I experiencing long washouts with SR2000™ Photoresist Film?

A – The SR2000™ is a light sensitive film. Do not wash film outside, indirect or direct UV light will expose film at a fast rate. If the photoresist film is exposed to UV light, then the film will not washout.

B – It is important to use the Rayzist hand sprayer to washout the photoresist film. The Rayzist hand sprayer produces a pressurized fan spray which is important for developing film. The distance from the Rayzist hand sprayer and washout board should be 1 – 2”. Wash in strokes from top to bottom of photomask.

C – The film print must be opaque not allowing any light to pass through the artwork image.

D – Exposure time on a Letralite™ unit is 20 seconds and Luminex 1422 is 6 seconds for 3Mil, 4Mil, & 5Mil, 25 seconds for 6Mil and 40 seconds for 9Mil. If the photoresist film is exposed for a longer period than the film will be began to absorb light and become difficult to washout.

Will the Rayzist hand sprayer provide enough pressure to washout 9Mil Photoresist Film?

The Rayzist hand sprayer will washout SR2000™ 9Mil. It is ideal for smaller surface area but may not be ideal for larger surface areas. A higher-pressure output sprayer will provide a faster washout.

How can I tell if my print is dark enough for the process?

A – Hold your print up to cylinder on the Letralite Unit and turn on the light. Confirm there is no light is passing through the artwork image. If light is passing through double check your print settings to ensure you have the darkest print setting possible.

B – Color laser printers are not recommended as they do not print a true black and as well as most laser printers. Inkjet printers are highly recommended for this process.

Lyndasglass –

I have been using Rayzist product for almost 20 years and I love the quality and reliability of their products. When I have had issues they were helpful at trouble shooting my problems and getting me back to work. I find their films consistently reliable and easy to use.

Sam J / SaM’sART –

I was getting another photoresist film from a local supplier in a 8.5×11 size. but I was not in a crunch mode so I got this as it was a little less expensive. I have done one washout with it and am quite impressed but as of yet I have not done the blast but feel I will like that as well.

Bob G / Axis Engraving –

I was using a different photoresist film but I had a large piece to sandblast and went with the SR2000 because of the larger format that it comes in and I’m glad I did. The first thing I noticed was that it held up VERY well in the washout process which the other film did not and it was much easier to work with because it doesn’t have a sticky coating. These not so little things made a big difference in my confidence level. I won’t be using any other photoresist film in my business.

Adam Ansley / An Etch Above –

Great Products! The mighty blue film has not let me down. I’m able to achieve amazing detail and it holds up great to sand blasting!

Kevin –

This works perfect every time it is fool proof. I use the 9mil for doing the pet memorials and the welcome rocks. I use the 3mil for the coasters and some of the glass. Great stuff from a GREAT company! Keep up the good work. Art is the Best!

John Penry –

I hadn’t purchased Rayzist in a while. I had been using a plotter and thick vinyl to do stones, but a friend asked me to do an order of about 50 goblets, so I got my Letralite out of the closet and ordered some Razist. I thought my Brother laserjet would make a dark enough image, but it was not as good as my old Epson inkjet. Wish I had been smart enough to order your new spray that darkens the laserjet image before I started.

I’ve always been happy with your products and service, and look forward to retirement when I can get my glass blasting started up again. Just two years to go.